5 ideas for more efficient Cold Press juice production

The correct use of your industrial juicing machine in the workroom, along with a suitable work routine, is vital for obtaining the highest profit margin. In this article, we bring together a number of best practices which will help you optimise juice production and increase profits in your natural juice business. Keep them in mind!

Not only will order, planning and correct handling of equipment allow you to obtain a higher number of juice units per hour, they will also reduce the fixed costs of your business. For example, you will have lower electricity and staff expenses, which will have a direct impact on your margin and therefore your profits month on month.

What do you need to design a more efficient juice and smoothies business?

1. Good design of the juice production process in your kitchen

This is a point upon which you should reflect before starting. Mistakes in process design are often made which are difficult to rectify later on. For this reason, before beginning, very good planning of what your kitchen will be like is important. It is very important for it to be linear, which means that each phase of the process must lead on to the next. Here are some tips:

- Define a space with one table for preparing fruit and ingredients, and another for filling bottles and capping.

- Design a spacious fruit and vegetable wash point with three sinks: rinse, disinfection and rinse.

- Separate the finished product from the raw material in your cold space (if possible in separate cold rooms).

- Have support tables with wheels at hand to transport the raw material and finished product.

- Work with a pressurised wash point and a good drainage system to prevent accumulations of water and aid cleaning.

Remember that for natural juice production, the phases, broadly speaking, are the following: reception of fruit and vegetables, washing, preparation, crushing and pressing, mixing juices and recipes, bottling and labelling. If each of these steps is not located straight after the previous step and with specific equipment dedicated to it, then you will waste a lot of time in the long run.

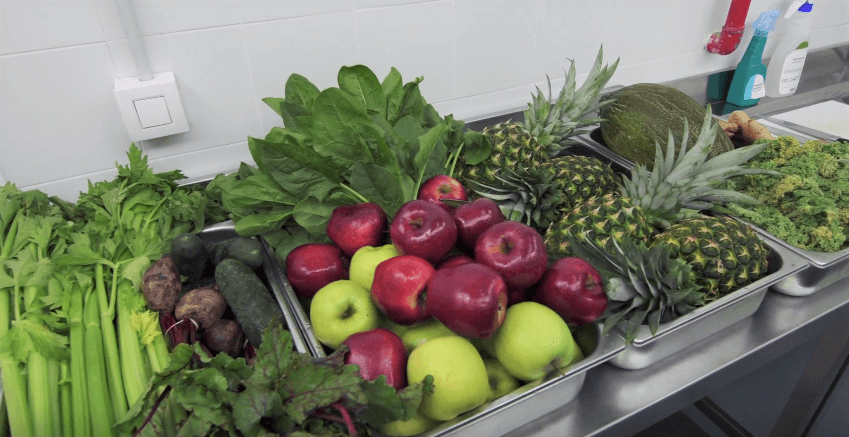

2. Preparation of the fruit and vegetables

Spend time preparing the fruit and vegetables before starting to process them. For example, in a Cold Press business, take into account that not all the fruit and vegetables need to be clean and ready for crushing before starting to press. You need just enough so that your industrial Cold Press machine does not halt due to lack of clean raw material. With experience, you will come know how much fruit and vegetables you need to prepare in advance and how much can be prepared while the Cold Press process is underway.

3. Try to press the fruit and vegetables only once

While you can achieve 5-10% extra juice by second or third pressings, the time involved can make it inefficient. This is especially the case with any fruit with a high water content that yields a large quantity of juice in the first Cold Pressing. If, in your business, production speed is less important and juicing efficiency more, carry out a second pressing to increase the final yield.

4. Work on the same recipe for as long as possible

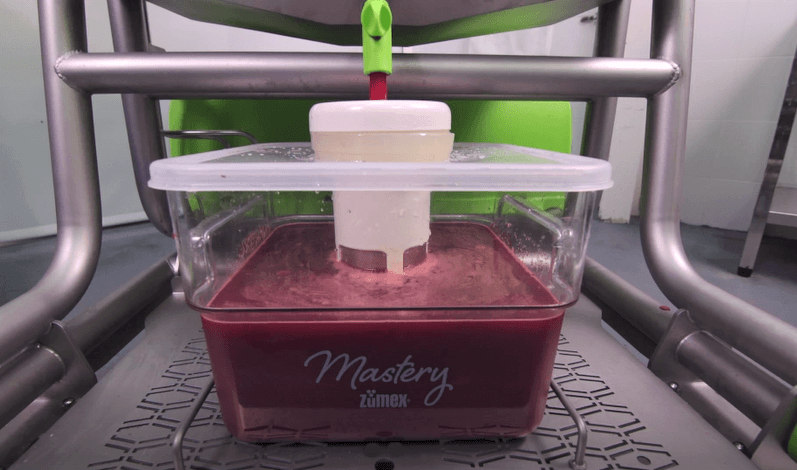

One of the things which can lose you the most time in juice manufacture is cleaning the machine and changing the bags and discs. Zumex Mastery is designed for fast and simple cleaning. However, if you try to prepare six recipes on the same day, you are always going to lose more time than if you only do two. Of course, your business requirements will dictate your activity and there will be days on which you sell more juices of a particular recipe, which you will have to rapidly replace.

Ideally, as you progress and make a sales record, you will adjust these forecasts to your production cycles in order to achieve the highest possible efficiency.

Discover how easy is to clean the Mastery juicer

5. Crush hard fruit and vegetables in small quantities (do not try to fill the chute up to the entrance, and fill the bag with around 10 kilograms of fruit as a minimum)

To crush as fast as possible, crush in small quantities (mainly when the product is hard such as carrots and beetroot). For example, if you try to fill the feeder up to the top, the crushing effort will be greater and the final time will also be longer. Also, do not try to fill the chute up to the edge as you will lose time attempting to put the fruit in place. Fill it up to ¾ and you will see that the crushing effort is much less, which will improve production speed. Sometimes “less is more”.

Also, fill the bag up to the mark indicated on the side to optimise performance. For example, if you fill the bag in small quantities (less than half), performance may be lower than if you fill the bag up to the marks. It is important not to exceed these marks in order to prevent breakages, splashing, pulp coming out, etc.

It may interest you: Tips for working more efficiently with your Mastery Cold Press juicer

In summary, take all these small pieces of advice into account even if they do not seem very significant when considered one by one. On taking stock of your work routines and performance, you will see that these small details can make the difference between a profitable natural juice business and one which is limited in growth and profits

About the Author

José Mataix

I oversee the business development of Zumex Food Engineering, our industrial division.

By leading the design of the Mastery project and as the manager for the business development of the JuiceTech line, and particularly of Mastery, I’ve had the opportunity to get to know Cold Press in depth, and to share the doubts and enquiries from our customers to lead them through the development and growth of their juice manufacturing business. Our objective is to remain close to our customers, to care for them daily and to accompany them over their business growth.

As a qualified agriculture and industrial engineer with 20 years of experience, I am prepared to solve any of your doubts on juice production processes.