How long does fresh juice last? Techniques to extend its shelf life

When beginning a project to sell natural juices, one initial concern is related to the conservation time of the juice and the processes that should be followed to extend its shelf life. To understand how the conservation of natural juices works, some of the methods currently used in the industry are explained below.

For years, the most common method was pasteurisation, which consists of heating the drinks for a determined period and at a determined temperature to extend the expiry date. With this process, it is possible to reduce the microorganisms present in food to levels that are not damaging to human beings. In this way, the shelf life of a product can be extended by several months if the containers are filled aseptically. As a result, the flavour and some properties of the juice are affected; in fact, some consumers believe that this process gives the juice a cooked taste.

At the moment, there are non-thermal conservation alternatives that leave the organoleptic and nutritional quality of the juice practically unchanged, ensuring that it remains similar to natural juice. We will look at some of these processes below in more detail.

Types of treatments using pasteurisation

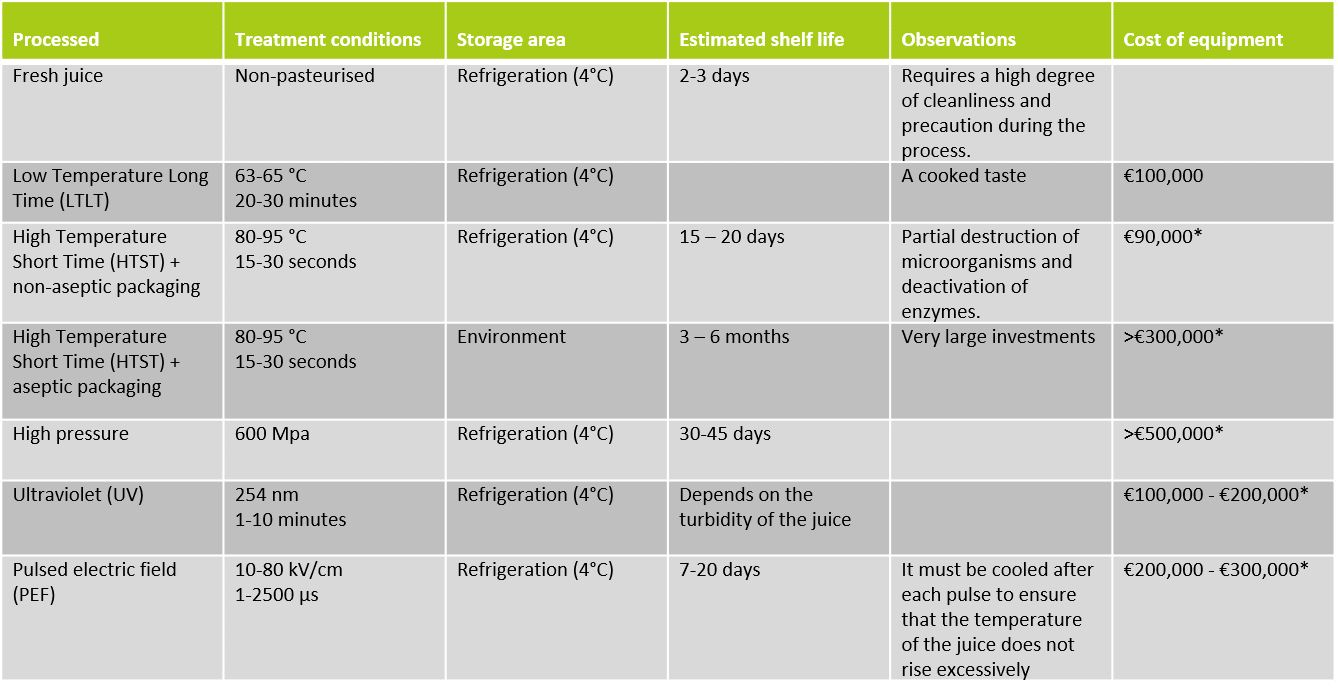

-

Slow pasteurisation (VAT) or Low Temperature Long Time (LTLT) pasteurisation

This was the most popular method when pasteurisation began. It consists of heating the juice to 63-65°C for 20-30 minutes and then allowing it to slowly cool. It can be necessary to wait up to 24 hours before continuing with the packaging process, which can be aseptic or non-aseptic. Today, this method has been replaced since it excessively changes the taste and quality of juices. Nowadays, the food industry has updated it with other more efficient systems that do not alter the flavour so much.

-

Flash pasteurisation or High Temperature Short Time (HTST)

It consists of heating the juice to a temperature that varies between 80 and 95°C for between 15 and 30 seconds. This is the most popular method in the juice industry since it results in minimal organoleptic and nutritional changes to the food, and it is also a considerably quicker method than the previous one. After this pasteurisation there is the option of aseptic or non-aseptic packaging. The main difference is the shelf life of the final product.

-

Ultra-Pasteurisation or Ultra-High Temperature (UHT).

It consists of subjecting the food product to a temperature close to 138°C for a couple of seconds. It is used in products with low acidity in which microorganisms capable of withstanding higher temperatures are found, such as milk. Through this technique, the shelf life of the product can be up to 6 months without refrigeration. It requires aseptic packaging and a major investment.

Consumers and the industry are increasingly demanding fresh products which have been minimally processed or cold-pressed. In this sense, there is a great variety of non-thermal conservation alternatives that could be interesting to use for these purposes. Among these alternatives, the most prominent ones are: high pressure processing (HPP), ultraviolet (UV) treatment or pulsed electric field (PEF), among others. High pressure processing is currently one of the most in-demand technologies, in which the temperature of the food does not increase, and its quality remains practically unaffected following processing. The negative aspect of this process is that it requires a large investment.

Non-thermal processing for juice conservation

-

UV treatment

Some companies have opted for this method since it does not increase the temperature of the food, and results in minimal changes in terms of its organoleptic and nutritional quality. It is less effective for juices with a high turbidity, since the treatment only reaches as far as the radiation.

-

Pulsed electric field (PEF)

This process also ensures that the nutritional and organoleptic quality of the product remains the same as the fresh version, although, in some cases it can give it a metallic aftertaste. The shelf life of the product is between 7 and 20 days in a refrigerator.

-

High pressure processing (HPP)

High pressure processing consists of submerging the juices, already packaged, in cold water and applying pressure of up to 600MPA for 3 to 6 minutes. This treatment ensures high-quality products and expiry dates of between 30 – 45 days when refrigerated.

It may interest you

Equipment and requirements for your Cold Press business

Key aspects of HPP juice treatment

In the United States, for example, to be able to sell on the distribution channel it is a requirement for natural juices to have undergone one of the previous processes in order to guarantee a 5-log pathogen reduction, in accordance with legislation. This means that it is necessary to use a thermal process capable of reducing the level of pathogenic microorganisms in juice by at least 100,000 times the total (before treatment).

In the food industry, this method is used to preserve products such as guacamole, pre-cooked food, juice, salsa, seafood and some others. This treatment destroys the microorganisms present in food, but it does not completely deactivate the enzymes and, besides, it is a technology that requires a great deal of investment.

Advantages of HPP compared to pasteurisation

- In HPP, the organoleptic and nutritional quality of the food is practically unchanged. However, in thermal pasteurisation, some nutrients are lost, and flavour changes can be noticed.

- The product is processed after it has been packaged, therefore aseptic packaging is not needed.

- No residue is produced, and clean energy is used, in accordance with current environmental policies.

A disadvantage of HPP compared to other alternatives is that it is a method that requires a large investment. Moreover, it is a batch process, meaning that time is lost in loading and unloading the product.

Furthermore, some of the c hemical preservatives often used to preserve juice can include potassium sorbate, citric acid or sodium benzoate. For a natural juice bar, it would not make much sense to add any of these artificial preservatives to products, however, you can consider using lemon juice in recipes as a natural preservative that, as well as enhancing the flavour of juice and having antioxidant properties for the human body, helps to extend the shelf life of juices that are produced.

Don’t miss this article: Steps to offer organic juices in my business

How long does natural juice last without being processed?

Finally, the most natural option that most Cold-Pressed juice bars use is that of not treating their juices. They do not even pasteurise them, which would not make sense when using the Cold-Press technique, nor do they use alternative treatments. Since the juices are usually going to be consumed the moment they are purchased or during the following days, and they are bought in the shop itself, it is often not necessary.

Worried about juicing storage? Have you ever wonder how long does juice last after juicing? The shelf life of natural juice varies between two and three days when refrigerated from the moment it is squeezed. As we indicated before, the presence of natural citrus, such as orange or lime, will help keep it longer.

When opening or growing a business it is important to be aware of all the options to make the best decision. For example, if the business is going well and it draws the attention of other businesses likely to offer juice, such as gyms, hotels or restaurants, the fact that you have presented a brand that does not use preservation methods could be difficult to change later.

How long does fresh juice last? Conclusion

The traditional processes of Pasteurisation, Ultraviolet and Pulsed Electric Field require continuous, low production maintained over a period of several hours for the same juice or recipe. These systems are useful when large quantities are needed. Also, they require ultra-clean or aseptic filling systems if the shelf life is to be considerably extended. With non-aseptic systems, the shelf life of the juice cannot be longer than 20 days in refrigeration.

The HPP system is perfect for small/medium productions since it can process batches of bottles with different recipes at the same time and from a single bottle to the maximum capacity of the machine. So the juice is processed after being bottled since it is not necessary to install aseptic filling systems. The shelf life of the juice is between 30 and 60 days in refrigeration. The main inconveniences are using PET as a packaging material and the high cost of the equipment. In any case, there are companies that offer tolling services. In this way, the bottles can be treated externally, and you pay per bottle without having to invest in your own machine.

Below, the main characteristics of the most popular preservation methods in the juice industry will be described.

*The prices will depend on the final output